| Type | BLZT—4080(BLDH seires can be equiped lath) |

| Input power | AC380/50Hz;AC220V/50Hz |

| Track gauge(mm) | 4035 |

| Effective cutting width(mm) | 3300 |

| Machine width(mm) | 4300 |

| Track length(mm) | 8000 |

| Number of standard cutting torch(set) | 2 |

| Number of lath cutting torch (set) | ≤10 |

| Minimum wideth of lath | 80mm |

| Lift(mm) | 200 |

| Cutting thickness(mm) | Flame: 5~200 Plasma: 1~30(According to the power supply size) |

| Cutting speed (mm/min) | Flame: 100~1000 Plasma: 450~5000 |

| Idle speed | 0~8000 |

| Drive mode | Bilateral drive |

| System | Shanghai Jiaoda or Beijing Starfire |

| Operating accurancy | ±0.5mm |

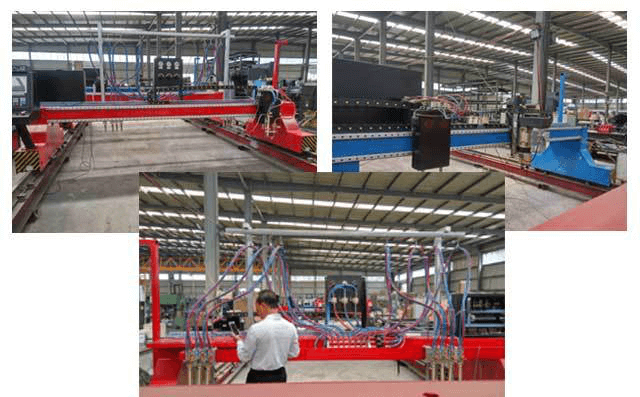

Plasma Flame cutting machine with 120A 200A 300A can be customized

It is the high efficiency flame cutting equipment that adopted the CNC cutting system. Multiple equal slots can be cut at one time and be widely used in steel structure industry with slat cutting. It is a kind of ideal equipment for steel structure plate making.☆ Product features:☆ Product description:☆ CNC plasma Flame Slab Cutting Machine (gantry straight line CNC cutting machine) :☆ Product parameters:| Number | item | quantity | specification |

| Model | BLDH 40100 | Bilateral drive, beam annealing to eliminate stress | |

| Rail apan (mm) | 3710mm | Effective Cutting Width 3000 | |

| Machine tool rail length (mm) | 8000mm | Effective Cutting Length 6500 | |

| CNC System (Set) | 1 set | F2300 B | |

| Transverse moving body (group) | Group 2 | flame | |

| Solenoid valve | Group 1 | Taiwan AirTAC | |

| Flame Cutting Torch Matching Components | 1 Set | Equipped with lifting body, automatic ignition device, solenoid valve group, matching air circuit, tow chain and TRVVP flexible control cable, etc. | |

| Flame cutting torch | 1piece+6pieces | national first-rate | |

| Pressure regulating valve and pressure gauge | 2sets | national first-rate | |

| Electric machinery | 3 pieces | Japan panasonic | |

| Driver | 3 pieces | Japan panasonic | |

| Reducer | 3 pieces | Taiwan AEVELE | |

| Guide | 1set | 24kg/55Q | |

| Drag chain | 1set | Guoyou | |

| Automatic Programming and Packaging Software | 1set | StarCAM | |

| Plasma cutting torch | 1 piece | 1pieceplasma gun | |

| Relay | 1set | OMRON | |

| Cutting mode |

| Plasma and flame straight strip cutting machine | |

| Device color |

| Black + Red (company standard color) |

| Serial number | Item |

Reachable index | |

| Lifting stroke of cutting torch (mm) | 1-150 | ||

| Cutting thickness (mm) | Flame cutting: 6-150 [Perforation 80] mm | ||

|

| Plasma cutting: mass cutting 25mm | ||

| Installation Accuracy of Guideway | 1). Side straightness of main rail: <0.3mm/3000mm 2. Side straightness of auxiliary guideway: <0.3mm/3000mm 3. Parallelism between the longitudinal rail surface and the horizontal plane of the main rail and the auxiliary rail: +0.2mm/1000mm | ||

| Intersection offset | ±0.2㎜ | A) Positioning accuracy and repetition accuracy of the whole machine: in accordance with JB/T5102-1999 standard B) Cutting Dimension Accuracy and Cutting Quality: Complying with JB/T10045.4-1999 Standard | |

| Straightness | ±0.3㎜ |

| |

| Roundness | ±0.2㎜ |

| |

| Diagonal difference | ±0.5㎜ |

| |

| Linear Repeated Positioning Accuracy | ±0.2㎜ |

| |

| Auto-tuning High Precision | ±0.3㎜ |

| |

| Accuracy of Lateral Linear Positioning | ±0.2㎜ |

| |

| Longitudinal Linear Positioning Accuracy | ±0.2㎜ |

| |

| Operating speed of the whole machine | 0-9000mm/min | ||

| Speed setting error (%) | ≤±5% | ||

| Cutting speed | Flame 0-5000mm/min | ||

| Cutting speed | Flame < 100um | ||

| Planarity of Cutting Surface | Less than 2.5/100*T (T is a thick plate) | ||

| Dimensional Accuracy and Straightness of Cutting Parts | ≤2mm | ||

| Working environment temperature | -5℃-50℃ | |

| relative humidity | 90% no condensation | |

| Surrounding environment | Ventilation, no impact within 5 meters | |

| supply voltage | 220V±5%, 380V±5% | |

| Power frequency | 50Hz | |

| Input power | Machine tool 2KW | |

| Grounding type | Centralized direct |